A customer approached us with an already developed Windows platform application — a simulator of hydrochloric acid treatment of a well. The task of the service is to simulate complex processes occurring in hydrochloric acid treatment to increase oil recovery with a positive economic effect.

The previously developed application is an MVP (a minimally viable product). He conducted several pilot calculations and signed contracts with oil-producing companies to further use the application.

The task was to develop a full-fledged service that will be easy-to-use and scalable, and used for independent operation by future customers.

Oil production

To better understand the mechanics of the service we have developed, let's pour ourselves a little into oil production technology.

Wells can have different configurations (vertical, directional, horizontal, multi-hole, and others), the choice of which depends on geological conditions and other factors. Oil-bearing formations (called "natural oil reservoirs") can have different lengths, capacities, compositions, and physical properties — the speed and volume of oil production depend on this.

Depending on the stage of field development, various methods of oil production are used. For the early field development, in fields with traditional natural oil reservoirs and high reservoir pressure, a fountain method of oil production is used. Oil moves to the wellhead due to its reservoir pressure. When the pressure drops, submersible pumps and flooding systems are used.

Currently, most of the fields are in the late stages of development. Prospective objects are characterized by a complex geological structure and low filtration and capacitance properties (low oil production rate). For an oil company to increase oil recovery, it is necessary to use oil recovery methods, such as hydrochloric acid treatment.

Problems

Since irreversible changes in the physical properties and characteristics of the oil reservoirs occur during hydrochloric acid treatment, much attention is paid to the quality and accuracy of the calculations performed.

The essence of hydrochloric acid treatment is that acid solutions are pumped into the well alternately and a diverter. Acid solutions are used to improve the filtration and capacitance characteristics of formations. Diverters are used to control the flow of acid solutions because the acid should be placed in those zones of oil reservoirs where it is necessary.

The complexity of the calculations lies in the dynamism of changes in a vast array of data:

- changes in the properties and characteristics of formations (20 parameters are taken into account for 10-40 formations at the same time);

- changes in the complex properties of the well after each processing interval.

At the same time, the following things act as limiters or variables in the calculations:

- existing pumping equipment parameters (what volumes of liquids, at what speed, during what time pumping is possible);

- characteristics of acid solutions (chemical properties of acids and diverters, their quantity, and presence).

The problem of the hydrochloric acid treatment is that if errors are made in the calculations, the opposite effect is possible — formation damage (colmatation) and a decrease in the permeability of formations, and, accordingly, a reduction in the flow rate of the well. The cost of eliminating the consequences of such errors can be tens of millions of rubles.

To eliminate such a problem and at the same time speed up calculations thousands of times and improve their quality, we developed a SaaS platform for oil engineers.

Mathematical model

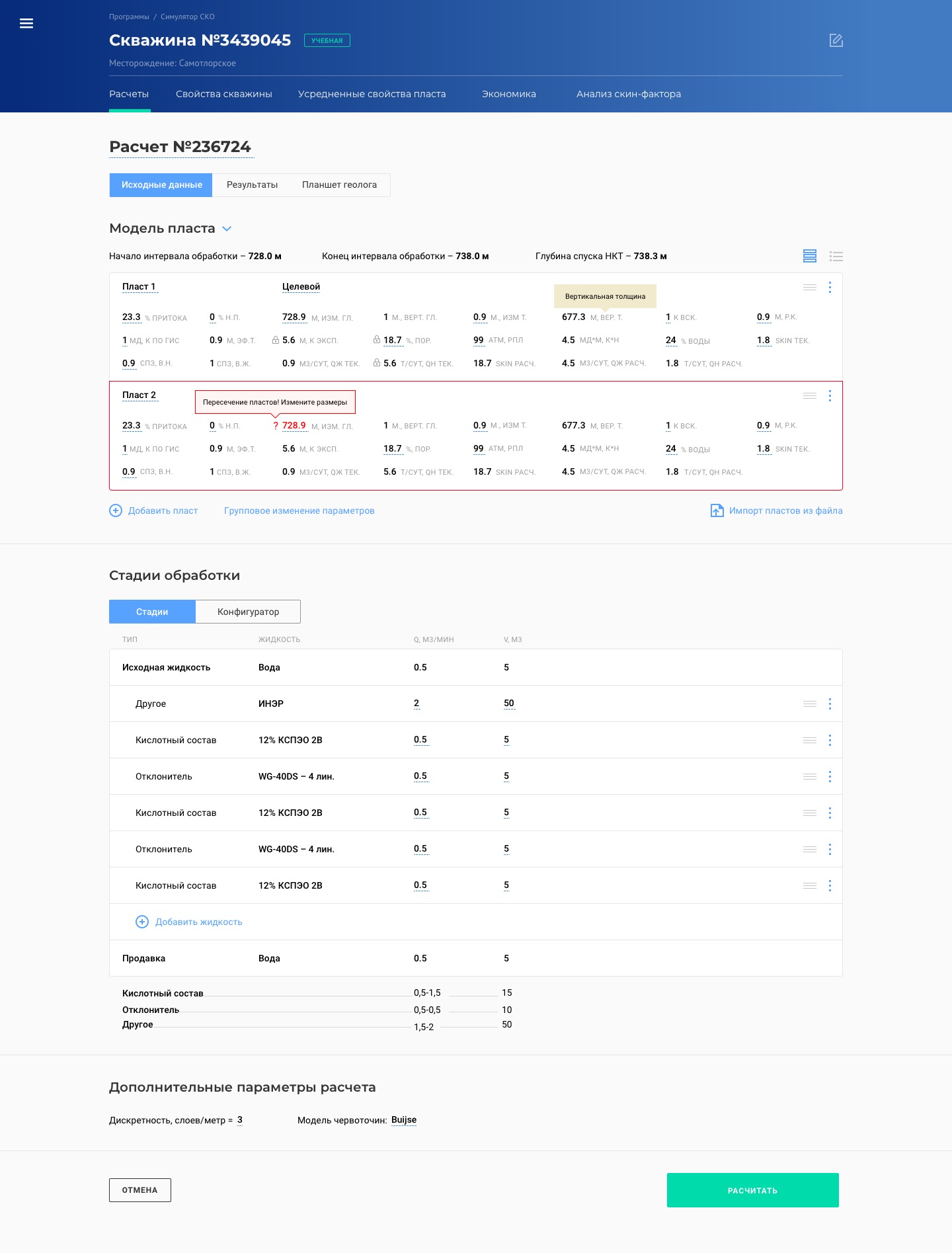

The simulator of hydrochloric acid treatments of wells is designed for modeling and optimal design of hydrochloric acid treatments of wells in natural oil reservoirs.

Depending on the oil reservoir pressure, fluid viscosity, field water-cut, the current skin factor (filtration resistance), the depth of contamination, porosity, and many other characteristics of the formations, as well as the properties of the injected acid solutions and parameters of the pumping equipment, our simulator calculate the optimal order, volume, and speed of the injection of acid solutions.

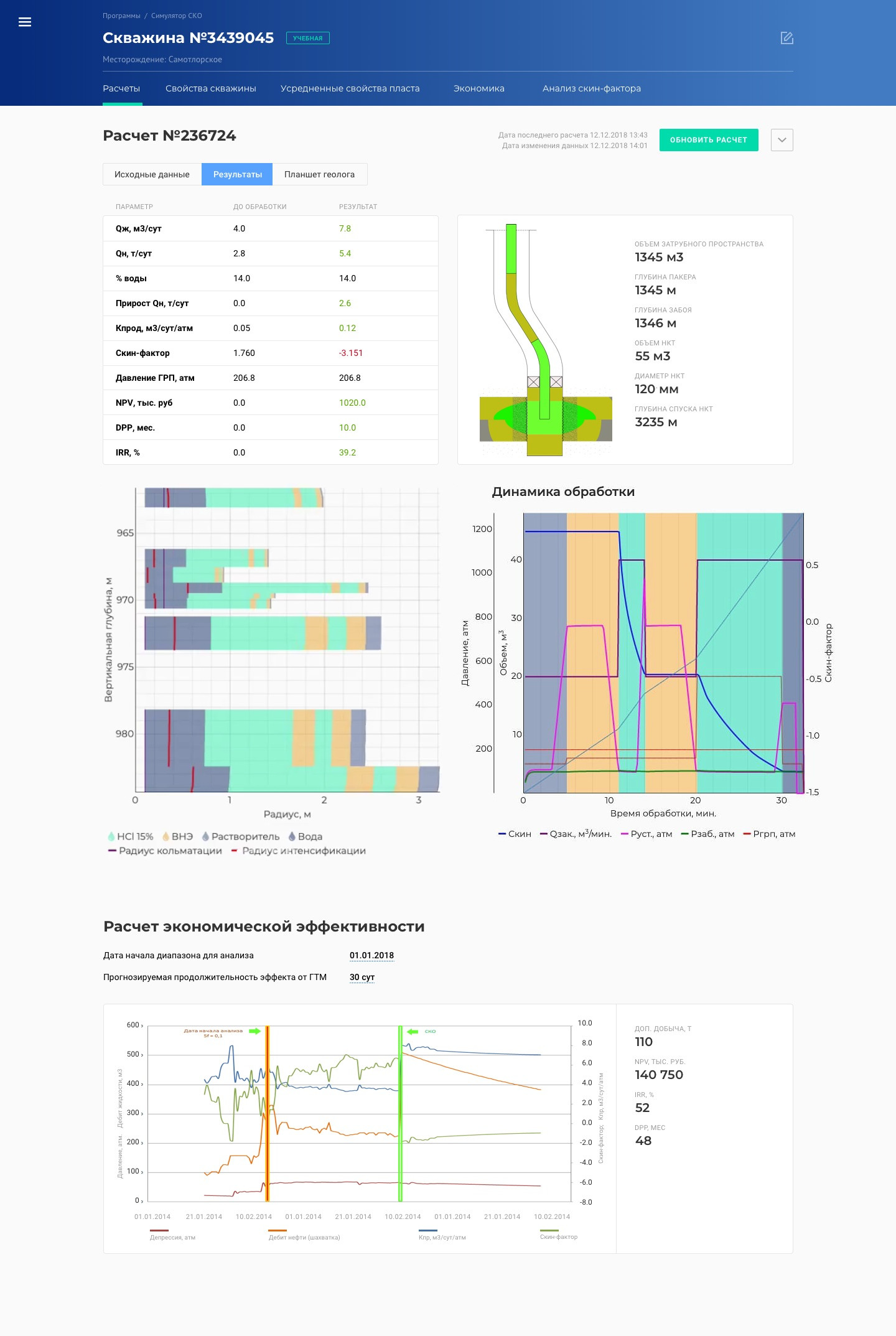

The goal is to reduce the skin factor and increase the flow rate of the well while increasing the economic efficiency of oil production (this means that the cost of measures for hydrochloric acid treatment of the well should be less than the cost of increased oil production).

To solve this mathematical problem, the customer (in the project, acts as an industry expert) has developed his mathematical model based on the Monte Carlo method, particularly the simulating annealing.

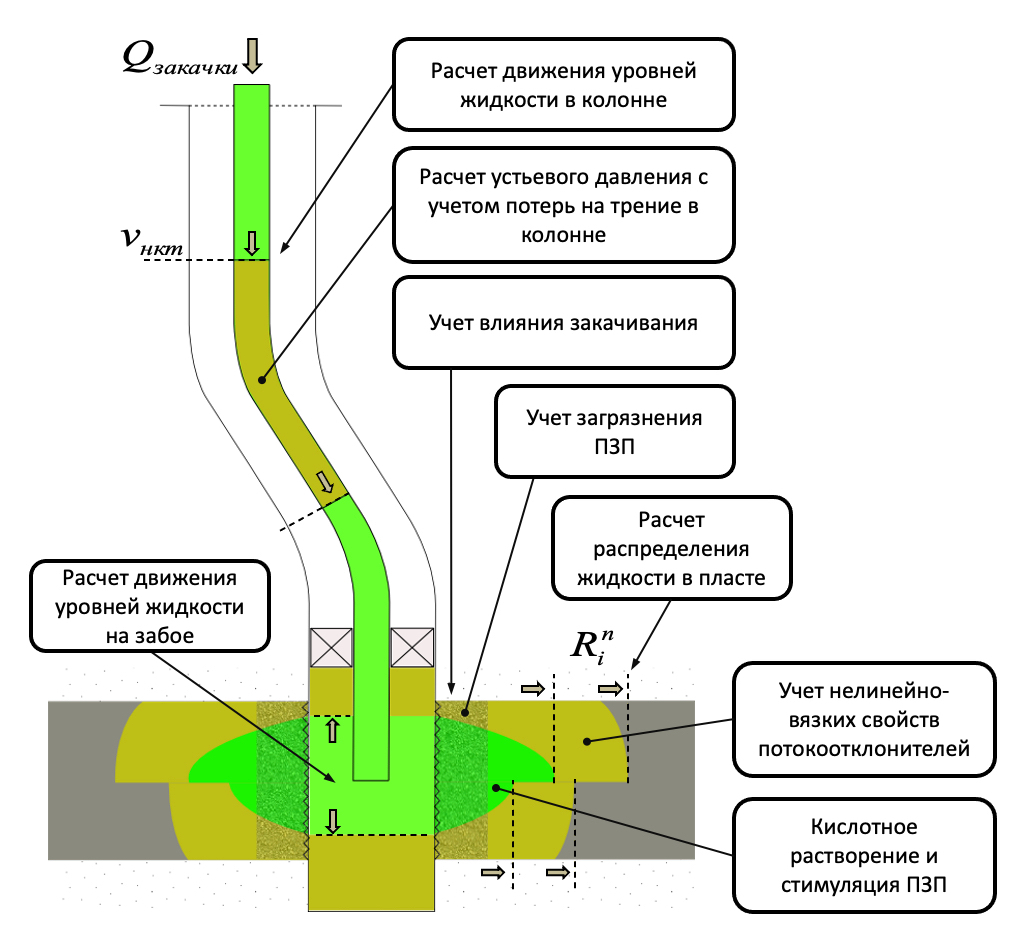

General scheme:

Features of the mathematical model:

- calculation of the depth of formation processing depending on the speed and volume of acid composition injection;

- calculation of the optimal parameters of the acid treatment design (speed and volume of injection), taking into account the maximization of the flow rate increase;

- calculation of the dynamics of bottom-hole and wellhead pressures;

- forecast of the increase in the flow rate of oil after the hydrochloric acid treatment.

SaaS platform

We decided to develop a cloud platform for fast scaling and availability on any user's device. We chose Ruby on Rails as the main framework. To significantly speed up mathematical calculations (on average, several billion analyses are performed for each well), we developed the mathematical core on Go language (golang).

We have designed and developed a user-friendly interface that is fundamentally new for the oil and gas industry. It allows you to control the parameters of wells and oil reservoirs from devices of various form factors (laptop, tablet, smartphone). Also, it eliminates the assumption of trivial errors when entering data arrays.

The system provides for the possibility of adding your pumping equipment and your liquids / acid solutions available at the enterprise but are not included in the program. It allows you to use not only pre-installed directories but also your own.

For a visual representation of the processes occurring in the oil reservoirs during hydrochloric acid treatment, we have developed a 2D animation of the distribution of fluid flows and changes in the permeability (degree of colmatation) of the oil reservoirs over time.

Results

In practice, the platform's calculations were used for the hydrochloric acid treatment of hundreds of actual wells of PJSC Bashneft and PJSC NK Rosneft. The convergence of the calculated and actual values was confirmed by more than 80%.

The platform became the starting point for creating a marketplace (application catalog) for oil engineers. Currently, simulators are being developed:

- modeling and design development of acid hydraulic fracturing;

- modeling and optimal design of repair and maintenance work;

- calculation of the parameters of the blocking pack and modeling of the well kill operation;

- forecasting of salt deposits in the reservoir and the well column during its operatio.